Cryo ln2 dewar

DSW engineers and manufactures long-lasting Cryogenic Storage Dewars designed to hold liquid nitrogen or helium with high-performance construction.

LN2 dewar is the most economical way to store and dispense liquid nitrogen, available in sizes ranging from a small 20 liters to a sizeable horizontal tank that holds 425 liters.

These liquid nitrogen dewars feature superior vacuum performance & insulation. Liquid nitrogen dewars are the most economical way to store and dispense liquefied nitrogen.

The liquid nitrogen Dewars is based on a proven design and construction and offers a wide range of capacities for individual laboratory storage and fluid nitrogen handling requirements.

These Dewars combine strength, high thermal efficiency, and ease of handling. The DSW Stainless Steel Dewar Flasks have an all-stainless steel construction, including vacuum Dewar, to be rust-free, anti-corrosive, hygienic, and strong.

LN2 Dewar, these portable dewars work equally well with liquified gas, liquid oxygen, and liquid argon for low-pressure transport & storage.

These liquid nitrogen Dewars can fulfill many different applications. These are simple, efficient liquid nitrogen tanks that can also be used for liquid oxygen or argon.

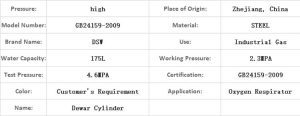

Cryogenic Storage Dewars specification

The Inspection Guarantee of LN2 Dewars :

The relevant welding seams will be subject to 100% RT non-destructive and penetrant testing (PT) according to the technological requirements of liquid nitrogen dewar production.

High-purity nitrogen (up to 99.999%) will be used for strength testing.

Finally, advanced helium mass spectrometer leak detectors (with precision up to 2×10-9Pa.L/s) will be used to conduct Helium mass spectrometer leak detection.

The inner containers of the storage tanks will be passivated by overall pickling to meet the cleanliness requirements for dangerous goods.

Imported ultraviolet black light lamps will ensure no oil stains and other organic impurities in the inner containers.

After cleaning, the inner and outer containers will be assembled at a time interval of less than 2.5 hours.

After assembling, the inner containers and interlayers will be filled with nitrogen to protect them from dust and organic impurities to ensure cleanliness.

The inner and outer surfaces of the outer containers will be subject to overall sandblasting treatment to meet the requirements of the Sa-2.5 standard.

When the surfaces of steel plates show a metallic color, a vacuum cleaner will suck off the dust adhered to the surface to ensure the vacuum degree in the interlayer further.

Special high-quality perlite is used as the insulation material in the interlayer.

The perlite will be treated using our company’s unique process before being in the interlayer.

All the internal cylinders, after being manufactured, will be subject to gas-tight and pressure performance tests.

The internal and outer cylinders will be subject to rigorous Helium mass spectrum leak detection.

After production, all the pipe openings will be opened to carry out nitrogen purging and replacement to meet the oxygen usage standard.

After this, all the pipelines and valves will be sealed, and the tanks will be filled with 0.2MPa high-purity nitrogen to protect the tanks.

The liquid nitrogen tank is a non-pressurized vessel specifically designed and made of materials that can withstand the extreme temperatures associated with liquid nitrogen.

Liquid nitrogen is odorless, colorless, tasteless, and nonirritating; therefore, it has no warning properties and must be carefully handled.