What are ISO tank containers?

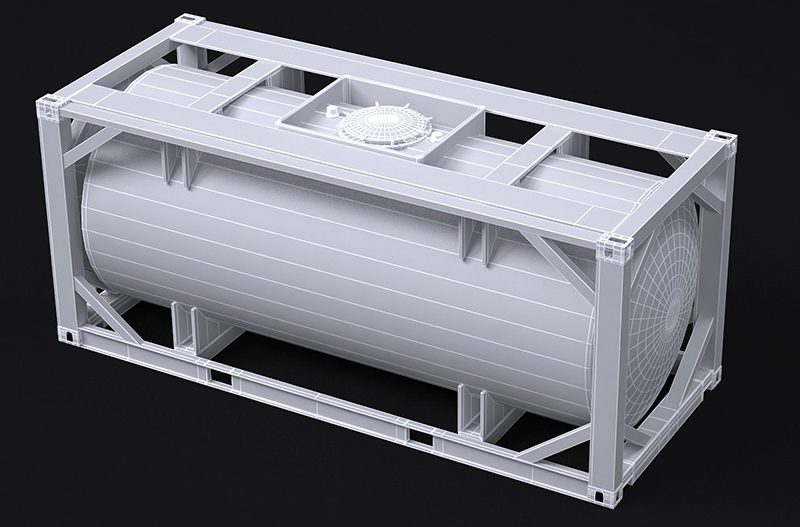

ISO tank containers are large, cylindrical containers used for transporting bulk liquids and gases. They are built to meet strict international standards, including those set by the International Organization for Standardization (ISO). These containers are typically made from stainless steel and have a capacity of between 14,000 and 26,000 liters. They are designed to be transported by road, rail, or sea, making them a versatile and cost-effective solution for a wide range of industries.

Benefits of using ISO tank containers.

ISO tank containers offer several benefits over traditional methods of transporting bulk liquids and gases. They are more cost-effective, as they can be easily transported by road, rail, or sea without additional packaging or handling.

They are also more versatile, as they can transport various liquids and gases, including hazardous materials. Additionally, ISO containers are more environmentally friendly, reducing the need for single-use packaging and minimizing the risk of spills or leaks during transportation.

ISO Tank Containers are used for the storage and transportation of hazardous and non-hazardous substances such as liquids. powders and gases. ISO tanks consist of stainless-steel with insulation and an aluminum or polyurethane protective layer. These tanks are safe and secure for transporting different types of materials.

ISO tanks are designed to transport the following items:

- Liquids

- Gasses

- Powders

- Chemicals

- Perishable and non-perishable food items

- Alcohol

- Non-alcoholic liquids

ISO tank containers have become synonymous with efficiency and safety. Tanks can transport large quantities of bulk easily, and they are also incredibly durable. Tank containers have a lifespan of 20 to 35+ years.

How do ISO tank containers work?

ISO tank containers work by using a combination of pressure and gravity to transport bulk liquids and gases. The containers are filled through a top-mounted valve and can be pressurized to help move the contents out of the container. They also have a bottom discharge valve allowing easy unloading of the contents. ISO containers are designed to be compatible with a wide range of transportation modes, including trucks, trains, and ships, making them a flexible and efficient option for transporting bulk liquids and gases.

ISO certification for ISO tanks

The International Organization for Standardization (ISO) upholds industrial and commercial standards for various products and services. This ensures consistency in both quality and reliability.

When a tank container is manufactured, it must comply with the ISO standards’ size, durability, and strength. Each tank is strictly inspected, and only then is it certified. The manufacturer also issues a container safety certificate (CSC).

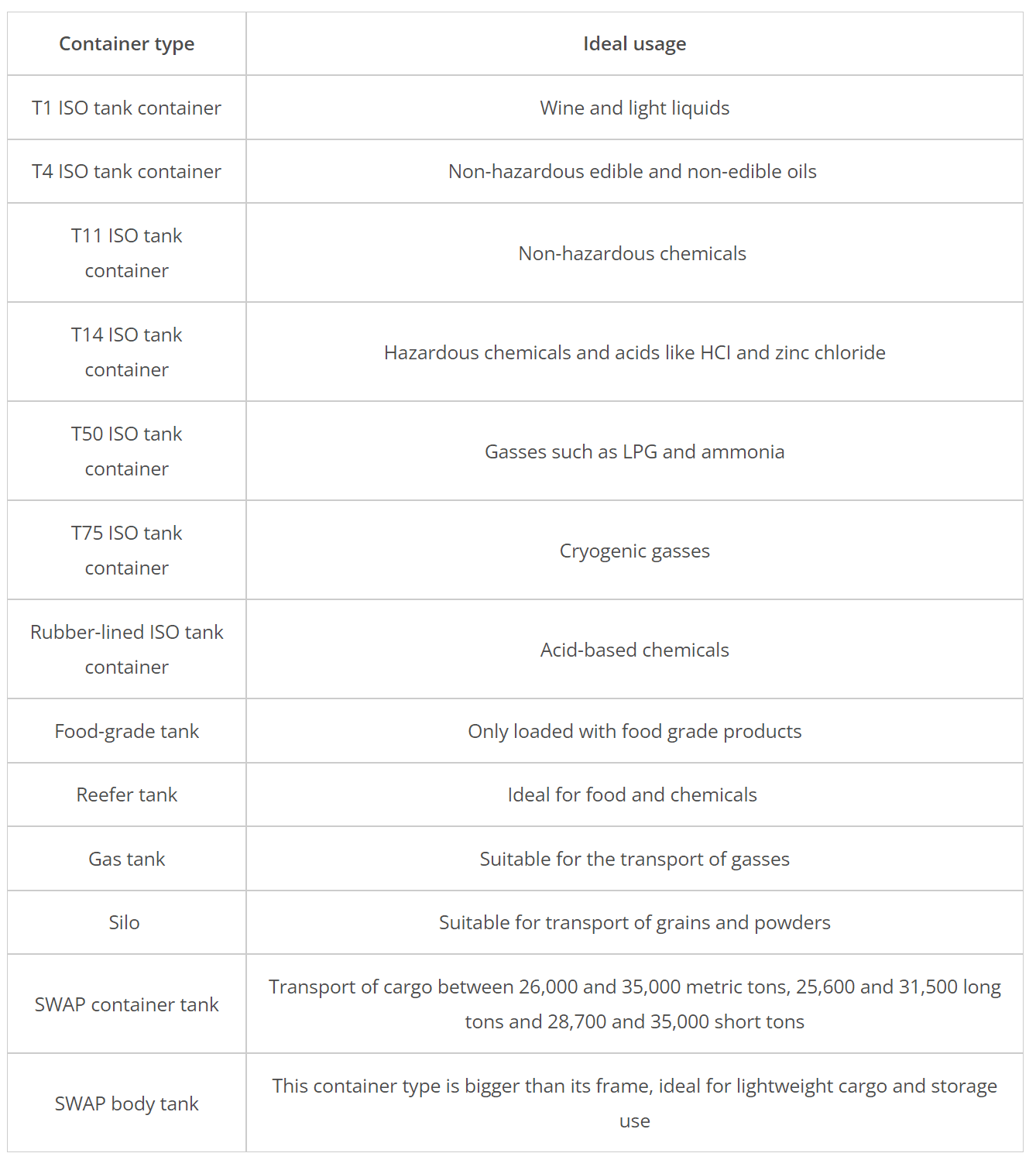

Types of ISO tank containers

Before you go ahead and buy or lease tanks, you should know that there are specific tanks for specific types of cargo. The chart below shows the different tanks and what they can transport and store safely.

Benefits of using ISO tank containers.

ISO tank containers offer several benefits over traditional methods of transporting bulk liquids and gases. They are more cost-effective, as they can be easily transported by road, rail, or sea without additional packaging or handling. They are also more versatile, as they can transport various liquids and gases, including hazardous materials. Additionally, ISO tank containers are more environmentally friendly, reducing the need for single-use packaging and minimizing the risk of spills or leaks during transportation.

Safety considerations when using ISO tank containers.

While ISO tank containers are a safe and reliable method of transporting bulk liquids and gases, several safety considerations must be considered. These include ensuring that the container is adequately cleaned and maintained, that the correct type of container is used for the specific material being transported, and that all necessary safety equipment, such as emergency shut-off valves and spill containment systems, are in place. It is also essential to ensure that all personnel handling and transporting ISO tank containers are adequately trained and equipped to do so safely.

No comment