Industrial Uses of argon

1. Argon Plasma Torch

Toxic metal dust is prevented from leaking into the environment by certain smelters using an argon plasma torch.

Hazardous dust particles passing through the torch are converted into a glob of molten scrap when the atoms of Argon are electrically charged to a temperature of 10,000°C.

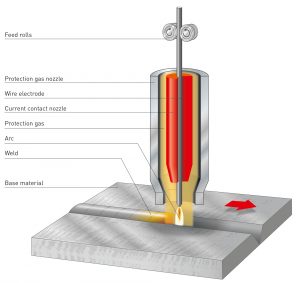

Very high temperatures are required for metal welding, and in the process, the metal reacts with elements present in the air, which leads to the formation of undesired products.

To tackle this issue, inert gases like Argon are utilized to assist the stabilization of the process of welding and avoid contamination.

Argon is one of the most often utilized shielding gases in welding and is regularly used as a foundation for specific mixtures.

Ar is frequently blended with a tiny amount of CO2 because it gives consistent quality and a cleaner finish to cut carbon steel.

Since Argon has a poor heat conductivity, welding using pure Argon is done when working with thinner metals such as Al, Ti, and Mg.

3. 3D Printing

The 3D printer needs an inert environment. Argon gas provides the same and prevents the undesired reactions to maintain the purity of components.

The 3D printing machine’s inert atmosphere keeps the oxygen concentration low, reducing oxidization in the created object.

Argon Gas, 3D Printing, and How to Stay Safe | PureAire Monitoring Systems Oxygen Monitor

4. Heat Treatment

It is the technique of heating metal so that the metal does not reach the molten state. The metal is then cooled in a regulated manner for choosing specific mechanical qualities.

Argon creates an inert environment and is typically provided at a dew point of less than -75°F and an oxygen level of less than 20 ppm.

Some heat treatment techniques that can benefit from an Ar atmosphere are annealing, brazing, and sintering.

5. The Chip’s packet: Storage

Instead of using nitrogen to preserve the chips, Argon can also be used. Argon’s density and size make it ideal for inerting.

Argon is eight-times more efficient than Nitrogen in lipids or water, because it allows oxygen extraction when it solubilizes.

It is an excellent respiratory enzyme inhibitor due to its similarity in polarity and potential for ionization to oxygen.

6. Uses of argon gas in Steel Manufacturing

AOD is used to decarburize stainless steels and special alloys such as silicon steel. Dilution of the essential elements by argon gas is a way to prevent unwanted oxidation.

7. Titanium Fabrication

Ti is used in many sectors. Titanium is highly sought after because of its corrosion resistance and high strength to density ratio.

In the final stage of titanium production, the molten metal Ti must be exposed in an atmosphere rich in Argon gas to avoid it interacting with other gases such as CO2 and O2 in the surrounding environment.

Even in an atmosphere rich in argon, a thin layer of titanium oxide is formed on the metal. This thin layer stops further oxidation. Once it is cooled, Ti can be used for most purposes.

8. Tires for Luxury Cars

Tires of high-end cars are filled with argon gas. Gas protects rubber from oxygen attacks and reduces tire noise when the car is moving at high speed.

Uses of Argon Gas in a Wide Range of Applications to Drive the Market Growth

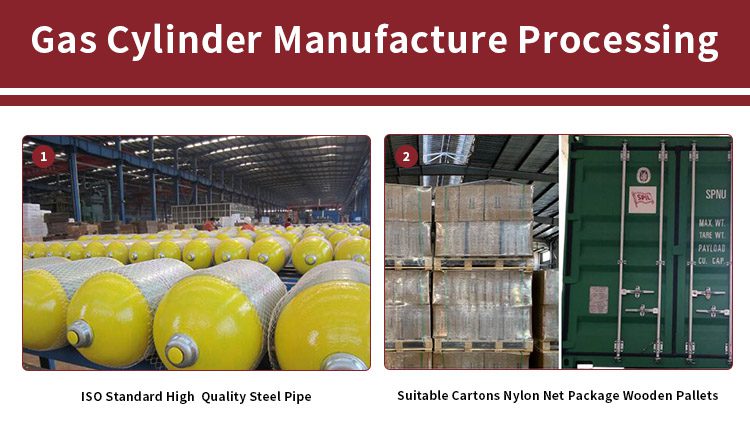

Argon gas is formed by fractional distillation by extracting it from liquid air in a cryogenic air separation unit and exists as charged ion molecules. It is a noble gas and, therefore, is considered an essential gas due to its wide range of applications across various industries, which is helping in increasing the demand for this gas and driving the market growth.

Argon gas is majorly used in the metal fabrication sector for shielding metals from oxidation during welding, because of its properties like non-toxic, non-flammability, non-reactive under extreme temperature conditions, and many others, due to which the demand for this gas is increasing in this industry. Metal fabrication is a subsector of the manufacturing industry and hence is linked with many other industries such as pharmaceutical, food and beverages, automotive, aerospace, energy, construction, shipbuilding, etc.(Use of Argon Gas)

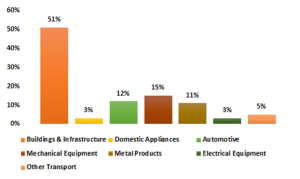

Metal fabrication has boosted the use of this gas in the steel industry, which is continuously booming, in all sectors across the globe. The below figure shows the use of steel in different sectors in the year 2018 (%).

Use of Steel, In Different Sectors, 2018

Uses of Argon gas

It is used in welding with a mixture of 95% argon gas and 25% carbon dioxide or 98% argon gas and 2% carbon dioxide, depending on the steel type.

In addition to this, it is also used on a large scale in solar and insulated windows to increase the energy efficiency and general performance of these windows which is increasing its demand in this sector and is driving the market growth. Furthermore, it is used in excimer lasers along with fluorine and helium, which are used for the production of microelectronic devices. It is also used in incandescent lamps and phosphorescent tubes which are propelling its demand due to the increasing number of malls, shopping complexes, hotels, etc.(Uses of Argon Gas)

Moreover, argon gas finds its applications in a variety of other purposes as well such as in the manufacturing of titanium and other reactive elements as a non-reactive blanket, for growing silicon as well as germanium crystals as a protective atmosphere, for filling the dry suits that are used for scuba diving, and as a filler gas in fire extinguishers and airbag inflation which are the factors responsible for the growth of this market.

No comment