Ethylene Oxide ETO Sterilization

Ethylene oxide (EO or EtO) is a low-temperature gaseous process widely used to sterilize various healthcare products, such as single-use medical devices. Using a vacuum-based process, EtO sterilization can efficiently penetrate the surfaces of most medical devices, and its lower temperature makes it an ideal method for a wide variety of materials.

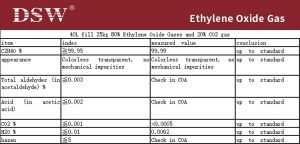

Due to its effectiveness and compatibility with most materials, ethylene oxide gas is an agent in the ETO sterilization of medical devices. ETO is a colorless gas that is flammable and explosive. The four essential parameters (operational ranges) are gas concentration (450 to 1200 mg/l); temperature (37 to 63°C); relative humidity (40 to 80%)(water molecules carry ETO to reactive sites); and exposure time (1 to 6 hours).

Of all the alternative sterilization methods available, ethylene oxide (EtO) sterilization arouses the most concern. ETO sterilization harms the environment and the body, whether used alone or mixed with CFCs. However, with adequate attention to the standards that will control EtO sterilization, its future should be relatively certain for a few years.

Ethylene Oxide Uses

Manufacturers primarily employ ethylene oxide to manufacture other chemicals for consumer and industrial use. One main chemical created from EO is ethylene glycol, used widely across products from brake fluid to industrial solvents.

EO is also used to produce healthcare products and sterilize medical devices.

Ethylene oxide uses include:

- Adhesives

- Agricultural insecticide

- Antifreeze

- Chemicals used to create fabrics for clothes, pillows, and carpets

- Cosmetics

- Detergents

- Fiberglass is used in jet skis, bowling balls, and other products

- Herbicide

- Household cleaners

- Industrial cleaners

- Medicines

- Polyethylene terephthalate (PET) plastic resin makes packaging and beverage containers.

- Shampoos

- Sterilizing medical devices that are too delicate or sensitive for high-heat sterilizing, such as knee implants, bandages, electronics, and devices containing plastic

- Sterilizing spices

EtO Sterilization

Although ethylene oxide sterilization (EtO) is commonly used in the manufacture of sterile medical devices, concern about residues of the sterilant in the sterilized products has led to an increase in the use of alternative methods;

however, these methods, in turn, have significant drawbacks. The authors have tackled the issue by investigating the possibility of reducing EtO residuals. After conducting a series of investigative experiments, it has been proved that EtO residuals may be reduced by decreasing the amount of EtO used in the sterilization process. This can be achieved without lowering the safe sterility level, and there are additional benefits for safety, cost, and the environment.

No comment