Argon Diaphragm Compressor

DSW’s Argon Diaphragm compressors pose no leakage threat to the atmosphere, offering an ideal solution for safely handling ultra-pure, corrosive, and volatile gases.

All DSW models can be designed to meet API 618 standards applicable to diaphragm compressors.

Our flexible configurations and sizes make them easily customizable to various applications in hydrogen processing, petrochemical refining, electronic gas specialty gas production, and polysilicon production industries.

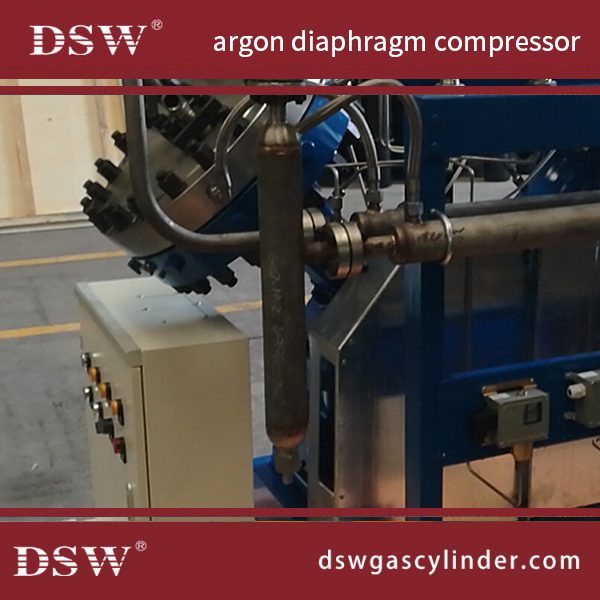

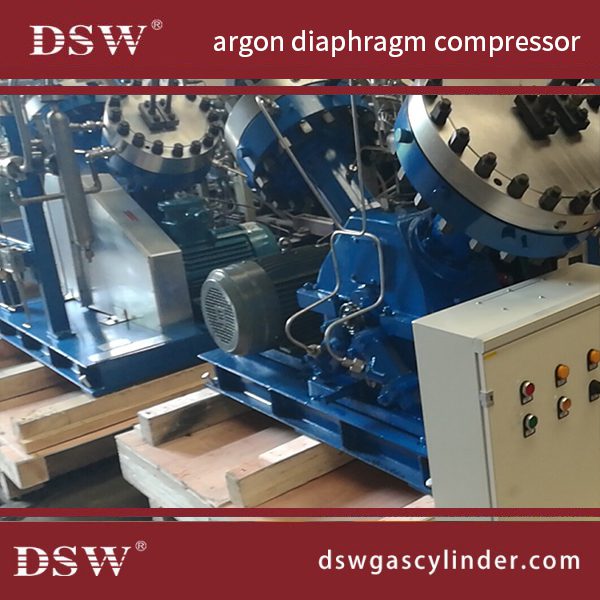

Argon Compressor And its Components:

1: Compressor

| Model: | GV-25/7-150 |

| Medium: | Ar |

| Type | V-style high-pressure diaphragm compressor with two cylinders and two-stage compressing |

| Discharge capacity: | 25Nm3/h |

| Discharge pressure: | 15MPa(G) |

| Intake condition: | 0.7MPa(G) |

| Rotate speed: | 400r/min |

| Lube type: | L-HM46 number of hydraulic oil (provide for oneself) |

2: Motor (supplied by requirement in contract)

| Model: | YX3-132M-4 |

| Type: | three-phase asynchronous motor |

| Rating Power: | 7.5kW |

| Rating rotate speed: | 1440r/min |

| Rating voltage: | 380V |

| Rating frequency: | 50Hz |

3: unit

| Size (length × width × height ): | 1600mm×900mm×1200mm |

| Unit net weight: | 1000kg |

What is a Membrane compressor?

Membrane compressors is the other name given to these devices.

Diaphragm Compressors, also called Membrane Compressors, are used for compressing gases with high purity and where leakage is not allowed.

Diaphragm Compressors are used for ultra-pure, toxic, poisonous, and flammable gases such as:

Anhydrous Hydrogen Chloride (HCI), Medical air/ Zero air, Argon, Nitric Oxide (NO), Carbon Monoxide (CO), Nitrogen, Ethylene, Oxygen, Fluorine, Radioactive gases, Heliox, SF6, Helium, Silane, Hydrogen, Xenon, Krypton, and other Special gases and gas mixtures.

Our Argon Compressors are preferred for high-purity and leak-tight gas compression applications.

DSW designs basic- to fully instrumented, leak-free, non-contaminating reciprocating diaphragm gas compression systems per customer specifications

Typical Application

Petrochemical

Speciality Gas

Energy

Silicon Manufacturing

R&D

Pilot Plants

Advantages of Diaphragm Air Compressor

The hydraulic framework reduces vibrations, knocks, and noise during compression.

This compressor offers oil-free compression thanks to its tight fit between the oil and gas frameworks.

Due to this oil injection process, the diaphragm compressor renders a better sealing performance. This also proves a tight compression of gas.

The diaphragm compressor provides compression without wear and tear.

DSW Compressor provides more than air compressor solutions; we offer comprehensive solutions for toxic or rare gas environments with high-value products such as toxic or rare gases.