Oxygen Air Separation Plant

The small-scale cryogenic air separation plant adopts a low-pressure process and extracts pure oxygen and pure nitrogen from the air by deep freezing and rectification.

The turbo expander refrigeration cycle principle liquefies the atmosphere according to liquid oxygen and liquid nitrogen boiling points.

The second rectification is performed in the fractionation tower to obtain 99.6% purity oxygen and 99.99% purity nitrogen.

According to needs, some liquid oxygen, liquid nitrogen, and medical oxygen can be produced by changing the operation

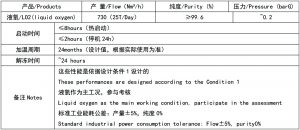

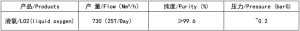

2、Main Technical Data

3. Performance Guarantee

3.1 Base conditions

The performance guarantee value of the plant specified in this project shall have the condition of a linkage test after the installation and acceptance of the device.

After the confirmation by party b, continuous performance assessment at full load (including mechanical performance assessment) shall be conducted, and the assessment results shall be taken as the basis for equipment acceptance.

3.2 Performance Guaranteed Value

Under the design condition 1, the equipment can meet the following output:

Basic Air Separation Unit (ASU) Components

Main Air Compressor (MAC)

The MAC compresses atmospheric air, generally to 60-90 PSIG, and delivers it to the system. Electric motors typically drive these compressors. Interstage coolers are provided to remove the heat of compression between each compressor stage, of which there are normally 2-3.

Front-End Cleanup

Modern ASUs utilize a Prepurifier Unit (PPU), which removes moisture, CO2, and most hydrocarbons from the air. Humidity and CO2 must be removed to prevent ice and dry ice from forming later. A PPU is typically made up of a chiller to cool the air to 40-55F, a condensate separator to remove free water, and two vessels filled with desiccant and mole sieve material, which adsorbs the contaminants while allowing the air to pass through. One bed is always online to the process, while the other bed is regenerated with heated waste Nitrogen to remove accumulated contaminants. Beds automatically switch every 5-8 hours. The air from the PPU is very close to moisture and CO2-free.

Some older ASUs utilize reversing heat exchangers to accomplish front-end cleanup. These systems contain special cryogenic heat exchangers that freeze out the moisture and CO2, allowing clean air to flow to the distillation process. The passes in the heat exchanger are switched every 3-10 minutes by a series of butterfly and check valves. One pass removes contaminates while outgoing waste gases regenerate the other.

However, moisture and CO2 removal by reversing heat exchangers is economical in terms of capital and operating costs.

Coldbox

The ColdBox contains the cryogenic heat exchangers, distillation columns, associated valves, and piping. Because parts of this system are icy, all components are mounted inside the ColdBox and then encased in insulation. Coldboxes can be rectangular or cylindrical and are usually tall, some over 200′ depending on capacity and type of Argon system.

Modern cold boxes are filled with perlite insulation, which is light and easy to install and remove when necessary. Older rigid boxes may be tightly packed with cryogenic rock wool, which is hand-packed to 14 pounds per cubic foot. It is very time-consuming to install and remove.

Expander

All ASUs except some tiny units have expanders. Expanders provide the required refrigeration to produce liquids in the distillation column system. Air, Nitrogen, or Waste Nitrogen is fed to the expander, causing the wheel to turn and transfer energy to a compressor, generator, or oil brake. This transfer of power causes the gas to cool. As the process continues, the outlet temperature of the expander eventually reaches the design temperature while cooling the column system.

Liquid Argon System

There are two common types of liquid Argon systems. Many plants don’t provide Argon separation equipment at all. In these cases, most Argon exits the ASU with the waste gas. The first type utilizes a crude Argon column that concentrates Argon to 2-3% O2 content from a feed from the low-pressure column of 88-92% O2. This crude Argon is warmed and mixed with Hydrogen before entering a catalytic reactor, where the H2 and O2 combine to make water. This wet Argon is then dried and again cooled to cryogenic temperatures, after which the H2 and N2 are removed in a separator and distillation column, respectively.

Cryogenic Argon systems depend solely on distillation for purification. Since it takes many trays or packing to separate Argon from Oxygen, these columns can be over 200 feet tall. Many new plants use cryogenic Argon systems to avoid using an Argon compressor and Hydrogen. The downside is the long recovery time to achieve purity after a start-up or upset the process, often over 48 hours.

Air separation equipment or Oxygen Air Separation Plant is an extensive complex system composed of the following subsystems: power system, purification system, refrigeration system, heat exchange system, distillation system, product transport system, liquid storage system, and control system.

It mainly refers to the raw air compressor. Air separation equipment, through low-temperature separation to oxygen, nitrogen, and other products, is essentially through energy conversion to complete. The energy of the device is mainly input by the raw air compressor. Correspondingly, most of the total energy consumption required by air separation is the energy consumption of the natural air compressor.

It comprises an air pre-cooling system (air cooling system) and a molecular sieve purification system (purification system). The compressed raw air has a higher temperature, and the air pre-cooling system reduces the air temperature through contact heat exchange. It can wash the harmful impurities such as acid substances in the air. The molecular sieve purification system further removes moisture, carbon dioxide, acetylene, propylene, propane, nitrous oxide, and other substances harmful to the operation of air separation equipment.

The refrigeration and heat exchange systems accomplish the air separation equipment’s heat balance. With the development of technology, the plate-fin heat exchanger is mainly made of aluminum.

The core of air separation equipment is essential equipment for low-temperature separation. High and low-pressure two–stage rectification is usually adopted as long as it consists of a low-pressure, medium-pressure, and condensing evaporator.