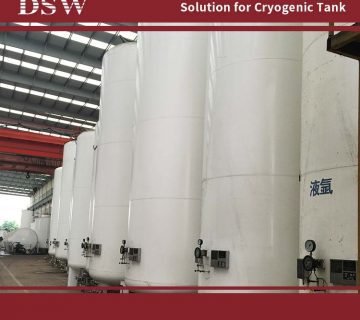

Cryogenic Vessels Manufacturer

DSW offers a complete line of Cryogenic Vessels, including the following types: flat-bottom cryogenic tanks, pressurized liquid storage tanks, dewar, cryogenic pumps for liquid oxygen (LOX), liquid nitrogen (LIN), liquid argon (LAR), and liquid carbon dioxide (CO2) service.

Design of Cryogenic Pressure Vessels

Depending on design parameters, tanks are produced to store the inner gas at -196 ºC or a less temperature. The cryogenic storage tanks, pressure vessels, and vaporizers are manufactured in China. As a design standard, CODE 2000, EN 13458, EN 13530, ADR 2009, and ASME Section is used.

The cryogenic vessels consist of two tanks, the Outer & Inner Tank. The inner tank is made of stainless steel 304L (X5 CrNi 18-10) & design code EN13458, While the outer one is made of CARBON STEEL & design code EN13458. The gap between tanks is filled with Perlite aggregation and superinsulation by vacuum technology. The manufacturing processes of the tanks are as follows: Tanks are produced to store the inner gas, at -196 ºC or a less temperature, depending on different design parameters. LIN, LOX, and LAR cryogenic storage tank capacities range from 300 to 80,000 gallons (50 tons). Vaporizers are also available in capacities – from 700 SCFH (20 Nm3/h) to 35,000 SCFH (1000) Nm3/h per unit. It also supplies Liquid CO2 storage tanks in sizes holding 3 to 50 tons of products.

Dewars and Cryogenic Vessels

Cryogenic storage vessels provide high-performance solutions for safe handling and long-term storage of large or small volumes of liquid nitrogen or other gases, including those corrosive substances like chemicals or acids. They are constructed of high-density materials for maximum resistance against chemicals or corrosion-producing liquids. Wide or narrow-mouthed openings allow easy transference and pouring without spillage.

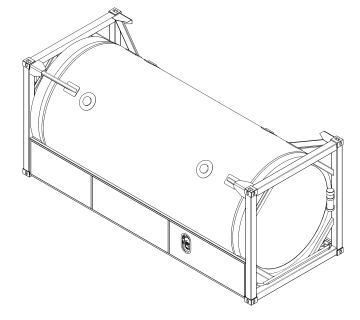

CRYOGENIC TRANSPORT TANKS

DSW International offers a complete line of liquid transport tanks for liquid oxygen (LOX), liquid nitrogen (LIN), liquid argon (LAR), and fluid carbon dioxide (CO2) services. Depending on design parameters, tanks are produced to store the inner gas at -196 ºC or a less temperature.

Cryogenic Liquid Tanks

Cryogenic Liquid Transportation Tanks are used for storing and transporting gases in liquid form. These Tanks are produced to keep liquid and gas according to the pressure condition requests of the customers. The inner tank is made out of stainless steel 304L (X5CrNi18-10 AS PER DIN 10028-7 OR EQU) & design code EN 13530 – 2002, while the outer one is made out of CARBON STEEL & design code EN 13530:2002.

DURA LIQUID CYLINDERS

DSW offers a complete line of Dura liquid cylinders. The Dura liquid cylinder is designed to transport, store and deliver oxygen, nitrogen, and argon as a cryogenic liquid or gas. Dura cylinders are vacuum and super-insulated vertical-type liquid cylinders with an in-built vaporizer that allows storage of cryogenic gases like oxygen, argon, nitrogen, and medical oxygen at a very low temperature ranging From -183deg c To -196 deg c. (Cryogenic Liquid Tanks)

CRYOGENIC PUMPS

DSW offers a complete line of Cryogenic pumps for Oxygen/Nitrogen/Argon Liquid from the cryogenic tank that is compressed to high pressure in a cryogenic liquid pump. It is then vaporized in an ambient air vaporizer to produce gaseous oxygen/Nitrogen/Argon. The high-pressure gas can then pass into cylinders via the gas manifold or be fed into a customer’s product pipeline.

No comment