ambient air vaporizer for the filling station

The ambient air vaporizers use heat from the air around them to vaporize a liquified gas. The simple operating principle means that these vaporizers don’t require external power. Several tubes are connected in series or parallel to move liquid gas. Ambient-air vaporizers find wide applications in many different industries.

DSW offers ambient air vaporizers designed for various applications. Each ambient air vaporizer is custom-sized according to flow requirements to prevent low-temperature gas from entering product pipelines. All ambient air vaporizers use innovative technology and reliable construction from DSW and come complete with custom solutions.

Application of ambient vaporizer

Vaporizers are responsible for vaporizing liquefied natural gas and other working fluids. It functions similarly to industrial boilers. Air Vaporizers are used for ethane, ethylene, and nitrogen. It also allows liquid or gas heat to pass to a second fluid. The two fluids do not come into direct contact with each other. Vaporizers generally work to heat or cool buildings or help engines and machines work more efficiently. They do not build up higher pressure and are commonly used for low-pressure heat transfer.

Available ambient air vaporizers:

Product vaporizer

Pressure building vaporizer

For product vaporizers, Cryonorm offers low- and high-pressure ranges.

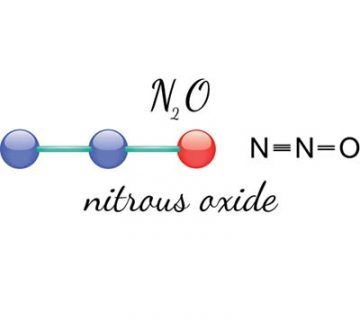

Ambient Air Vaporizers are custom-sized to meet customer flow requirements based on gas type (O2, N2, AR, CO2, CO3, CH4, C2H4, etc.), duty time requirement, ambient conditions, and desired gas temperature downstream from vaporizer(s).

Industrial ambient vaporizer

A wide range of cryogenic Industrial ambient vaporizers is available in the industry. To pick the best vaporizer system, one must understand how each works. The key benefits of using a cryogenic vaporizer can provide various benefits. It eradicates the re-condensation of vapor in the supply lines, which may create dangerous situations. Moreover, it eliminates the ‘freeze-ups’ of tanks, resulting in production delays or loss. Even heavy-end accumulations can be prevented. It helps to decrease overall costs and even delivery frequency. Besides, a vaporizer also increases the entire system’s capacity.

Thus, vaporizer has many benefits; their significance is undeniable. Types of Vaporizers Ambient Air Vaporizer: It channels heat from the air to vaporize low-temperature liquids, including cryogenic ones. It can vaporize oxygen, nitrogen, CO2, argon, LNG, other cryogens, and even liquefied gases.

No comment