CNG Composite Cylinders Manufacturer

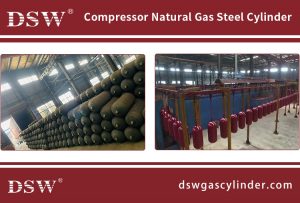

DSW Industry has been manufacturing composite cylinders, fiber gas cylinders, and gas equipment components for CNG vehicles since 2007.

Our commitment to quality and innovation has made us a trusted supplier in the industry.

These carbon composite oxygen cylinders, such as those used by firefighters and EMTs, are designed for professionals needing to transport cylinders frequently. These cylinders are compact, durable, and resistant to cracking and tearing.

Researchers, staff, and contractors store and use various compressed gases for different reasons.

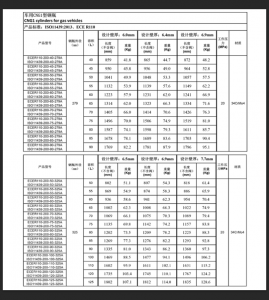

CNG Composite Cylinders, which can store natural gas under pressure 20MPa or 25MPa, are made of 4130X seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval.

They are explosive pressure vessels containing flammable and combustible gases.

The storage pressure for automotive cylinders is 20MPa.

During the loading of natural gas, pressure should reach 216 bar. Safety above international standards is provided.

Cylinders are calibrated according to the pressure above 300 bar and designed to resist 450 bar.

The test period for cylinders should be five years.

Tested cylinders are labelled. Retested and relabeled cylinders can be used for five years or more.

Lightweight Composite Gas Cylinders

DSW’s high-integrity composite cylinders offer high capacity and lighter weights, providing unrivalled portability and ease of use.

- Type 2: Hoop-Wrapped Cylinders

- Material: Metal liner (usually steel or aluminum) with a composite wrap.

- Features: The composite material is wrapped around the metal liner in the hoop (circumferential) direction, reinforcing and reducing weight compared to all-metal cylinders.

- Type 3: Fully Wrapped Composite Cylinders with Metal Liner

- Material: Metal liner (usually aluminium) fully wrapped with composite materials (carbon fibre or glass fibre).

- Features: These cylinders are lighter than Type 2 because they use less metal, relying more on the composite material for strength and pressure containment.

There are four categories available in CNG gas cylinders.

The first category is seamless alloy steel cylinders (CNG-1).

CNG-2 is a composite gas cylinder with steel or aluminum lining and a barrel reinforced

with long fibers impregnated with “hoop winding” resin.

The third category is composite gas cylinders with aluminum liner plus carbon fibre fully

wound and glass fiber ring wound reinforcement (CNG-3).

The fourth category is the composite gas cylinder with plastic liner plus carbon fiber

full winding and glass fiber ring winding reinforcement (CNG-4).

Each of these Compressed Gas cylinders has its advantages and disadvantages, and it depends.

The main cylinders used worldwide are steel cylinders, generally made from high-quality

chromium-molybdenum steel, and the ISO 11439 and ECE R110 standards can meet

the requirements of most countries.

At DSW, we pride ourselves on delivering high-quality composite cylinders that meet stringent safety and performance standards.

Whether for industrial use, automotive applications, or emergency services, our cylinders provide reliability and peace of mind.