Compressed Gas Cylinder

Compressed gas cylinders are pressure vessels designed for the storage and containment of gases at a higher pressure than atmospheric. Used in many workplaces for gases ranging from highly flammable (acetylene) to inert (helium), many compressed gas cylinders store gases with up to 2,500 PSIG of pressure for safekeeping – often for welding or cutting steel surfaces. Industrial compressed gas cylinders may also be employed as part of an oxy-fuel welding and cutting system.

What Does Compressed Gas Mean?

Compressed gasses are stored under pressure in cylinders. There are three primary types of compressed gases: liquefied, non-liquefied, and dissolved gases. Pressure in each cylinder is usually measured in pounds per square inch gauge (psig) or kilopascals.

Liquefied gasses are liquid at normal temperatures when they are inside cylinders under pressure. Common liquefied gasses include ammonia, chloride, propane and nitrous oxide. Non-liquefied gasses are also known as compressed, pressurized or permanent gasses. Oxygen, nitrogen, helium and argon are all examples of non-liquefied gasses. Acetylene is the only common dissolved gas and is very unstable chemically.

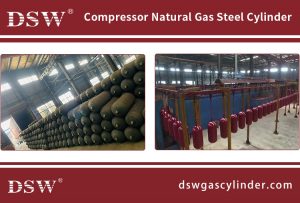

CNG Gas Cylinders which can store natual gas under pressure 20MPa or 25MPa are made of 4130X

seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval.

which are explosive pressure vessels containing flammable and explosive gases.

The storage pressure for automotive cylinders is 20MPa.

There are 4 categories available in CNG gas cylinders.

The first category is seamless alloy steel cylinders (CNG-1).

CNG-2 is a composite gas cylinder with steel or aluminum lining and a barrel reinforced

with long fibers impregnated with “hoop winding” resin.

The third category is composite gas cylinders with aluminum liner plus carbon fiber fully

wound and glass fiber ring wound reinforcement (CNG-3).

The fourth category is the composite gas cylinder with plastic liner plus carbon fiber

full winding and glass fiber ring winding reinforcement (CNG-4).

Advantages of Compressed Gas cylinders

The main cylinders used worldwide are steel cylinders, generally made from high-quality

chromium-molybdenum steel, and the ISO 11439 and ECE R110 standards can meet

the requirements of most countries.

A complete automotive CNG cylinder has a cap, a valve, and a safety relief device.

The cap protects the valve and the safety relief device on the valve should be of

the rupture disc-fusible plug combination type.