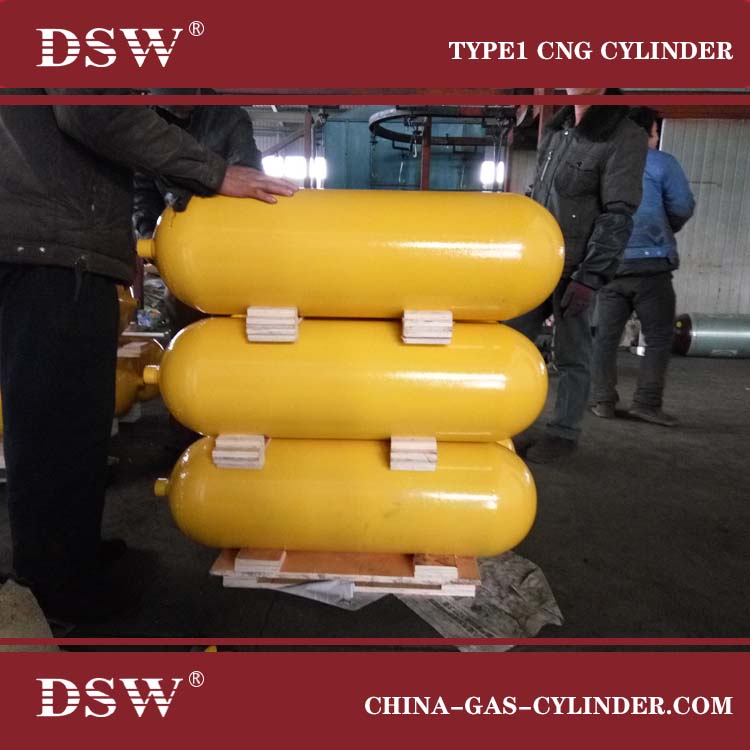

Type 1 CNG storage tanks Supplier

DSW Industry supplies Type 1 CNG Storage tanks in various sizes to store compressed natural gas.

This high-pressure container containing flammable and explosive gas is a pressure container with explosive danger. The gas storage pressure of the vehicle gas cylinder is 20MPa.

Specification of CNG GAS CYLINDERS

The steel cylinder is made from 4130X seamless with a design wall thickness of 5.9 mm. Its outer surface is covered with a resin-based glass fiber composite.

The composite is wrapped in mixed fibers: low-angle winding, high-angle winding, and hoop-winding. The finite element method is used to perform stress analysis and optimize autofrettage of the composite gas cylinder.

The designed composite gas cylinder complies with ISO 11439-13, and after optimization of autofrettage, the gas cylinder has the best autofrettage of 52 MPa.

CNG TANK SIZES CHART

Compressed Natural Gas CNG Storage Tanks

Type 1 CNG Gas Cylinder, which can store natural gas under pressure 20MPa or 25MPa, made of 4130X seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval.

Which are explosive pressure vessels containing flammable and combustible gases.

The storage pressure for automotive cylinders is 20MPa.

The steel walls of Type 1 CNG storage tanks are approx. 0.5 to 1.5 inches thick, making them the heaviest type of CNG storage tanks.

A standard Type 1 cylinder has a diameter of 11 inches for the smallest and 16 inches for the largest. Type 1 cylinders have a history of reliability and durability.

There are four categories of CNG gas tanks.

First, we have seamless alloy steel cylinders.

CNG-2 composite gas cylinders have a steel or aluminum inner lining and a reinforced barrel.

With long fibers impregnated with “hoop-wound” resin.

Composite gas cylinders are the third category, with an aluminum lining and carbon fiber entirely.

CNG-3 is a ring-wound glass fiber reinforcement with a wound surface.

Fourth category: Composite gas cylinders with plastic liner and carbon fiber

Full winding with glass fiber ring reinforcement (CNG-4).

The advantages and disadvantages of each Compressed Gas Cylinder will vary.

CNG cylinders are the most common cylinders in use worldwide. They are generally high-quality.

ISO 11439, ECE R110, and chromium-molybdenum alloy steel can all meet the ISO 11439 standard.

The requirements of the majority of countries.

The complete CNG tank for an automobile has a cap, valve, and safety release device.

The valve cap and safety relief device should be in place.

The combination of a ruptured disc and fusible plug.