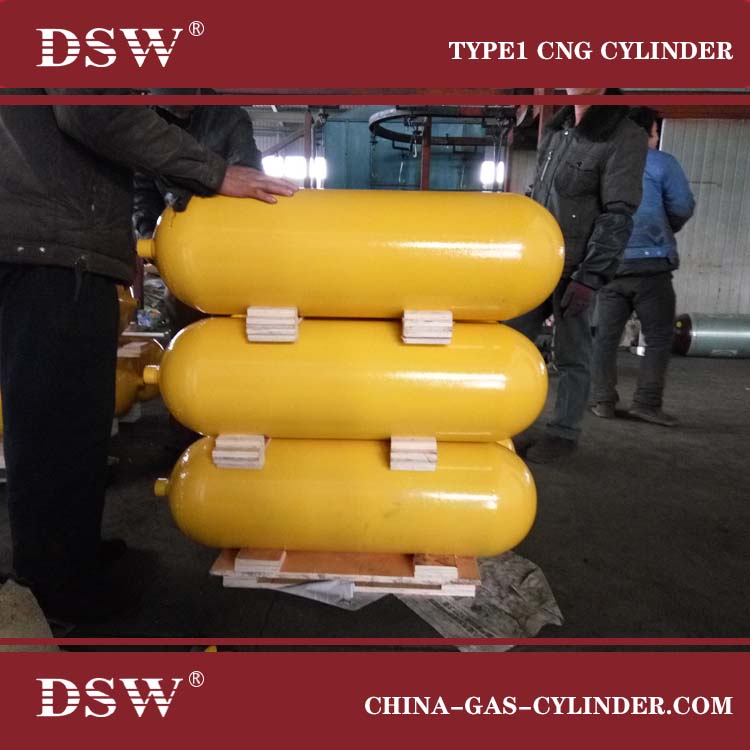

ISO11439 Type 1 CNG Tank

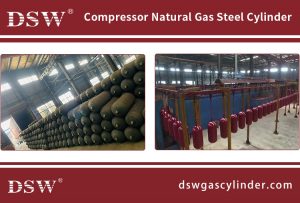

DSW industry is a leading CNG tank manufacturer used for flow forming, automotive and heating, and water industries with valves, nozzles, brackets, and more.

Our compressed natural gas tanks are DOT and NGV-compliant and tested to the highest standards, guaranteeing your safety with every use. Natural gas’s physical properties, as well as our CNG fuel systems designed to comply with stringent quality requirements, contribute to its high levels of safety, making compressed natural gas an extremely secure fuel option.

Researchers, staff, and contractors store and use various compressed gases for different reasons.

Type 1 CNG tanks are constructed of solid steel for durability. Perfect for installation beneath vehicles and at a highly reasonable cost.

What is Compressed natural gas (CNG) ?

Compressed natural gas (CNG) is a fuel gas composed primarily of methane (CH4) compressed to less than one percent of its volume at standard atmospheric pressure. Stored and distributed using hard containers at pressures between 20-25 megapascals (2,900-3,600 psi), typically cylindrical or spherical shapes are utilized for storage and distribution of this product.

CNG can be utilized in modified traditional gasoline/internal combustion engine vehicles or vehicles specifically manufactured to accommodate CNG usage.

TYPE 1 Compressed Natural Gas Tank

Type 1 CNG Tank which can store natual gas under pressure 20MPa or 25MPa, are made of 4130X

seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval.

which are explosive pressure vessels containing flammable and explosive gases.

The storage pressure for automotive cylinders is 20MPa.

There are four categories available in CNG Tanks.

The first category is seamless alloy steel cylinders (CNG-1).

CNG-2 is a composite gas cylinder with steel or aluminum lining and a barrel reinforced

with long fibers impregnated with “hoop winding” resin.

The third category is composite gas cylinders with aluminum liner plus carbon fiber fully

wound and glass fiber ring wound reinforcement (CNG-3).

The fourth category is the composite gas cylinder with plastic liner plus carbon fiber

full winding and glass fiber ring winding reinforcement (CNG-4).

Each of these Compressed Gas cylinders has its advantages and disadvantages, and it depends.

The main cylinders used worldwide are steel cylinders, generally made from high-quality

chromium-molybdenum steel, and the ISO 11439 and ECE R110 standards can meet

the requirements of most countries.

A complete automotive CNG cylinder has a cap, a valve, and a safety relief device.

The cap protects the valve, and the safety relief device on the valve should be of

the rupture disc-fusible plug combination type.