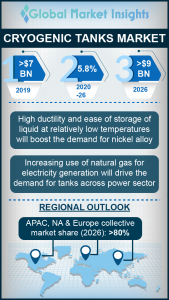

Top 12 cryogenic tank suppliers

Cryogenic tanks are devices that can store super-cold fuels such as liquid nitrogen gases, liquid hydrogen gases, and others. It exhibits liquefied gases at -150°C or lower. But it has been witnessed that the increase in natural gas and industrialization fuel the demand for cryogenic tanks. The cryogenic tanks’ primary application is observed in several end users, such as LNG and energy sectors. The cryogenic tank market is rapidly increasing globally due to exporting goods from one country to another, such as petroleum, chemicals, machinery & equipment, marine ships, etc.

Cryogenic liquids exist at shallow temperatures, so specialized equipment is required for transportation and storage. Contrary to popular belief, it’s not just possible to store cryogenic liquids in a standard container.

Doing so would make it impossible to handle them and also present health and safety risks to those working with them. Cryogenic tanks are built for this express purpose.

They’re manufactured with durable materials that can withstand such low temperatures. Additional precautions are also built into the equipment to reduce any chances of leakage.

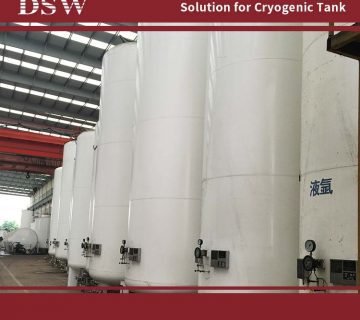

DSW Industry offers a variety of products, including ISO containers, bulk storage tanks, liquid dewars, and self-pressurizing vessels. This cryogenic tank manufacturer also provides a wide range of services, including custom design, repairs and refurbishments, and the provision of spares.

What is a cryogenic tank?

Cryogenic tanks store cryogenic liquids such as liquid nitrogen, helium, argon, etc. Cryogenic tanks also store gases like liquefied natural gas and nitrous oxide at higher temperatures.

These tanks need to be thermally insulated to maintain low temperatures. This is achieved through the use of a vacuum jacket. This component must be designed and manufactured to a high specification that follows established international design codes.

Cryogenic vessels can be of several different kinds. Static or fixed tanks, such as a cryogenic processing facility, are used in a selected location. Stationary tanks also include small mobile tanks mounted on wheels for use in labs and workshops.

These small cryogenic tanks are also known as pressure vessels. Non-pressurized open-neck containers called Dewar flasks are also available in scenarios requiring direct access to the cryogenic liquid.

Reproducing cryogenic tanks is possible, but it’s not a job that just about anyone can do. Any repairs or modifications to such tanks should be carried out by a skilled repairer who performs the job per the design codes to which the tank was manufactured.

They also need to be mindful of the prevailing regulations and legislation.

Any repairs or modifications must be documented so that records can be kept for as long as the tank is in service.

What is Cryogenic Storage in Cryogenic Equipment?

Cryogenic Storage refers to storing Cryogenic liquids used for their low-temperature properties. Cryogenic liquids are icy, with boiling points below -150°C. Such fluids include liquid helium (-269°C), liquid hydrogen (-253°C), and liquid nitrogen (-196°C), which is the most widely used cryogenic liquid.

Cryogenic Liquid Storage Tanks

Containers

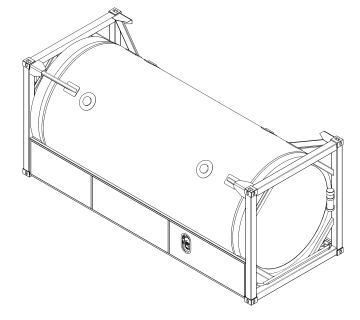

Cryogenic liquids can be transported, stored, and handled in various containers depending on quantity and desired use. Cryogenic tank containers (ISO-containers) are widely used to transport atmospheric gases (oxygen, nitrogen, argon) and LNG in intermodal transport – by sea, road, and rail.

Dewars

Dewars are non-pressurized, double-walled containers used to contain cryogenic liquids. The area between the walls is under high vacuum for maximum thermal insulation. They have a loose-fitting insulated cap that enables gases to escape while preventing moisture buildup at the neck. They are often used in “satellite” cryogenic liquid containers within a lab.

Dewar flasks

or cryogenic flasks are smaller, double-walled cryogenic storage containers that usually only maintain the liquid for a few hours. They typically have a metal outer wall and a glass inner wall, with void space under a high vacuum. Special care should be taken when handling as these flasks can implode.

Cryogenic Liquid Cylinders

Cryogenic liquid cylinders, sometimes called Dewars, are insulated, vacuum-jacketed, pressurized vessels. They come equipped with safety relief valves and rupture disks to alleviate pressure buildups. These cylinders come in various sizes ranging from 80-450 liters. They can be fitted to provide gas through an internal vaporizer or provide liquid under their internal vapor pressure. The users usually fill these cylinders at filling stations throughout the campus. All users must wear proper PPE when filling and discharging. Cryogenic cylinders routinely relieve their internal pressure, and you may observe a sudden hissing sound and the appearance of fog. This is entirely normal. When using cryogenic cylinders, users should ensure that all valves and pressure relief devices are in place and good condition. If pressure relief devices fail, catastrophic failure may result.

Cryogenic Storage Tanks

A few buildings on campus have cryogenic storage tanks. These are filled by vendors on a set schedule and are used to fill the end user’s cryogenic cylinders and dewars.

Who are the leading Manufacturer of cryogenic Vessels?

The top 12 cryogenic tank manufacturers & cryogenic tank suppliers are Listed in Cryogenic Tank Market Report.

● Chart Industries

Chart Industries, Inc. is a leading independent global manufacturer of highly engineered equipment servicing multiple Energy and Industrial Gas market applications. Our unique product portfolio is used throughout the liquid gas supply chain to produce, store, distribute, and end-use atmospheric, hydrocarbon, and industrial gases. The chart has domestic operations across the United States and an international presence in Asia, Australia, Europe, and Latin America.

● Cryofab Inc.

Cryofab, Inc. is a cryogenics company and one of the critical cryogenic tank suppliers in the global cryogenic equipment marketplace. We manufacture and service cryogenic storage and accessories, offering custom and standard fabrications to customers worldwide. We offer a wide range of cryogenic containers: tanks, dewars, vessels, hoses, and valves of all sizes allowing for the safe storage and transportation of all cryogenic gases. Our cryogenic dewars can store and transport liquid helium, argon, liquid oxygen, liquid nitrogen, liquid hydrogen, and liquid natural gas (LNG). Cryofab offers ASME, DOT, and PED products. Our in-house cryogenic engineering experts can assist with product development of OEM or private label fabrication of cryogenic tanks, whether it be prototype or production runs, for industrial, laboratory, medical, biotechnology, pharmaceutical, superconductivity, semiconductor, or even homecare applications.

● Cryogas Equipment Private Ltd

● Cryoquip Australia

For nearly 75 years, Cryogenic Industries, Inc. and its member companies have manufactured engineered cryogenic equipment and small-scale process plants for the liquefied natural gas (LNG), well services, and industrial gas industries.

Cryogenic Industries is the parent company of Nikkiso ACD, Nikkiso Cosmodyne, and Nikkiso Cryoquip and a commonly-controlled group of 20 operating entities, including Nikkiso Cosmodyne India (formerly Rhine Engineering), Nikkiso ACD Cryo (Europe), Nikkiso Cryoquip Australia, Nikkiso Cryoquip – U.K, and Nikkiso Cryogenic Industries Service Companies.

● Eden Cryogenics

Eden Cryogenics is a cryogenic tank manufacturer that specializes in cryogenic equipment. It offers engineering, design, and manufacturing of cryogenic and high vacuum equipment, such as cryogenic vessels, helium refrigerators, cryopumps and cryopump systems, heat exchangers, cryogenic compressor skids, cryogenic test systems, cryostats, vacuum insulated piping, and custom-engineered systems. The Company also provides a line of cryogenic valves, couplings, and filters. It serves energy, laboratory, and aerospace facilities.

● FIBA Technologies

FIBA Technologies, Inc. is a leading global provider of gas containment equipment and services for industrial gas, chemicals, specialty gas, offshore oil and gas exploration, and alternative fuel industries around the globe. Founded in 1958, FIBA is continually focused on its goal of providing safe, technologically advanced, and superior products to its customers on time. As markets needing cryogenic equipment and services expand, we remain committed to delivering excellence and pushing the industry forward.

● Gardner Cryogenic

Gardner Cryogenics designs and manufactures high-performance, highly reliable, long-lasting storage tanks used to transport hydrogen and helium molecules around the globe. With more than five decades of experience, Gardner provides customers with industry-leading technology enabling them to move and store molecules with near-zero loss cost-effectively. The unique technology developed by Gardner provides the lowest heat leak for the highest yield when transporting, storing, and transferring helium and hydrogen.

Our experienced team of cryogenics experts works with our customers to leverage our technology to meet their specific storage, transportation, and budget needs.

● Linde AG

Linde AG, an international technology company, operates in two business segments: Gas and Engineering and Materials Handling. The company produces industrial and medical gases, develops plants for gas production, and is one of the biggest manufacturers of industrial trucks in the world. In 2004, Linde exited the refrigeration business, in which it had been Europe’s market leader.

● Suretank Group Ltd

Founded in 1995 in Co. Louth, Ireland, Suretank is a leading engineering solutions company with 27+ years’ of experience designing & manufacturing certified products, services, and solutions.

As one of the leading cryogenic tank suppliers. Suretank provides Modular Solutions (OSM), Offshore Tank & Container Solutions & Bespoke Pressure Vessel Solutions to the Energy, Marine, Infrastructure & Industrial sectors.

● VRV SpA

VRV S.p.A. designs and manufactures pressure cryogenic equipment for chemical, petrochemical, power, and cryogenic industries.

The Cryogenic Division engages in the design and manufacture of cryogenic equipment for the transport, storage, and distribution of liquefied technical gases, such as nitrogen, oxygen, argon, LNG (natural gas), hydrogen, and other hydrocarbons for use in industrial, healthcare, electronics, food, energy, and environmental applications. It offers standard cryogenic bulk storage tanks, shop-built engineered storage tanks, site-built custom-made storage tanks, cryogenic distribution equipment, micro bulk cryogenic tanks, ambient air vaporizers, nitrogen tanks, cryo solutions, turnkey systems, liquid helium dewars and tanks, homecare medical systems, and vacuum insulated piping.

● Wessington Cryogenics

Wessington Cryogenics is an engineering-led, solutions-driven, and customer-focused Manufacturer of cryogenic vessels.

Founded in 1984, this UK-based Company provided small tanks for industrial and medical research applications. Almost 40 years, and tens of thousands of tanks later, Wessington now operates from a 70,000-sq.-ft. The facility where its 130+ employees deliver vessels all over the world.

The organization has many products, including bulk storage tanks, liquid helium dewars, self-pressurizing vessels, cryogenic equipment, ISO containers, and road tankers. These are joined by an ever-increasing range of services, including custom designs, repairs, and refurbishments, as well as the provision of spares and accessories.

A cryogenic tank manufacturer with a proud pedigree of engineering innovation, Wessington’s special projects are amongst some of the most interesting in the cryogenics field, including bespoke vessels for use in particle physics, ‘Around the World’ ballooning records, hydrogen, and other green energy cryogenic applications.

No comment